XTRAIA XD SERIES

HIGH-RESOLUTION XRD EPITAXIAL FILM CHARACTERIZATION

HR-XRD METROLOGY TOOLS FOR BLANKET AND PATTERNED WAFERS.

XRR, XRD, Rocking curve, RSM, including multi-layer thickness and composition analysis.

XTRAIA® XD SERIES

In-line XRD and XRR Metrology Tools with down to 40 µm beam.

For 200 mm and 300 mm Wafers

- High resolution X-ray beam

- 2 dimensional detector

- Stage and goniometer

- Analysis software

- Full automation function

BENEFITS:

- Assure product quality

- High yield

- Compelling cost of ownership

- Productivity metrics

XTRAIA® XD-3200

HR-XRD and XRR, XRD, Rocking curve and RSM

Up to 300 mm Wafers

- For Blanket Epitaxial Thin Films (e.g. Si/SiGe multilayer)

- 9 kW rotating anode X-ray generator (optional 2.2 kW sealed X-ray tube)

- Line focus with mirror and/or 2/4 bounce crystal

XTRAIA® XD-3300

HR-XRD and XRR, XRD, Rocking curve and RSM

Up to 300 mm Wafers

-

For Blanket/Patterned Epitaxial Thin Films

-

Dual-beam (Line and 40 µm micro-spot)

-

Pattern recognition

METROLOGY SOLUTION for a wide range of applications

Transistor, LED/LD, MEMS, Sensors, New Memory, Metal film, and Multi-layer films.

XTRAIA XD-SERIES Metrology Tools for accurate analysis of thickness, density, and roughness of the surface and boundary of thin films deposited on a wafer.

Determining the incident and exit angles of the X-ray beam at intensity maxima in the spectrum, the strain, and hence lattice parameters, of the individual layers.

This High-resolution XRD Metrology Solution combines x-ray reflectometry (XRR) for film thickness analysis and x-ray diffraction (XRD) for estimation of the film crystallinity.

XTRAIA® XD SERIES SYSTEMS SPECIFICATIONS

| SYSTEM PARAMETERS |

XTRAIA® XD-3200 |

XTRAIA® XD-3300 |

| Metrology Type | HR-XRD High-resolution X-ray Diffraction and XRR X-ray Reflectivity | HR-XRD High-resolution X-ray Diffraction and XRR X-ray Reflectivity |

| Wafer Size | 200 mm, 300 mm | 200 mm, 300 mm |

| Wafer Type | Blanket | Blanket and Patterned |

| Wafer Transfer | Loader, EFEM (Dual Port) | Loader, EFEM (Dual Port) |

| X/Y Stage Parameters | X: -150 to 150 mm Y: -150 to 150 mm Z: 0 to 9 mm φ: ±180° χ: -5° to 90° |

X: -150 to 150 mm Y: -150 to 150 mm Z: 0 to 9 mm φ: ±180° χ: -5° to 90° |

| Sample Handling | Double arms for wafer | Double arms for wafer |

| Automation | GEM300 | GEM300 |

| SW User Interface | Windows10 – Automation, analysis, and recipe software | Windows10 |

| X-ray tube energy | 9 kW Rotating Anode or 2.2 kW Cu Sealed Tube | Option 1: 9 kW Rotating Anode or 2.2 kW Cu Sealed Tube Option 2: COLORSTM Hybrid |

| X-ray Optics | Max. 2 monochromators Ge (400)x2,Ge(220)x2,Ge(220)x4 | Option 1: Max. 2 monochromators Ge (400)x2, Ge(220)x2, Ge(220)x4 Option 2: COLORSTM Hybrid |

| Detector Type | 2D (HyPix-3000) | 2D (HyPix-3000) |

| Small Spot Size | - | Yes |

| Pattern Recognition | - | Yes |

| High Intensity | Yes | Yes |

| Chi Axis | Yes | Yes |

| Goniometer | θs:+85°, θd:+85° | θs:+85°, θd:+85° |

| Dimensions | 1656(W) x 3689(D) x 2289(H) [mm] Main unit (With load ports) 602(W) x 1521(D) x 1080(H)mm Water chiller (With a base pan and power box) |

1656(W) x 3689(D) x 2289(H) [mm] Main unit (With load ports) 602(W) x 1521(D) x 1080(H)mm Water chiller (With a base pan and power box) |

| Standards | SEMI S2/S8 Other: CE Compliant | SEMI S2/S8 Other: CE Compliant |

EXCLUSIVE RIGAKU TECHNOLOGY

HyPix-3000 Detector

This sophisticated X-ray metrology tool makes it practical to perform high-throughput measurements on product and blanket wafers ranging from ultra-thin single-layer films to multi-layer stacks.Highly capable metrology is enabled by world-class key components include high brilliance source technology, multi-layer optics, and state-of-the-art 2D detectors with ultra-high dynamic range and high sensitivity.

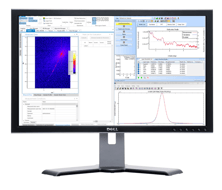

CONTROL AND DATA PROCESSING SYSTEM

Analysis software XRR, RSM, XRD, Rocking curve, RSM including multi-layer thickness and composition analysis. User-friendly interface.

Rocking Curve: Simultaneous measurement of focusing X-rays using 2D detector

COLORSTM X-ray Optics: An automatic crystal monochromator selector (high throughput / high resolution)

Explore Semiconductor metrology Solutions

Who we are

Rigaku Semiconductor Metrology Division

Semiconductors have the power to change the world for the better. Here at Rigaku, we strive to make this a reality as the leading global supplier of X-ray metrology tools for semiconductor process R&D and high-volume manufacturing.

To contribute to the enhancement of humanity through scientific and technological development.

Value our customers, value our people, and value our technology.