TXRF-V310

WAFER SURFACE CONTAMINATION METROLOGY

simultaneous VPD AND TXRF

FOR THE HIGHEST THROUGHPUT

MEASUREMENT OF ULTRA-TRACE ELEMENTAL SURFACE CONTAMINATION

TECHNICAL SPECIFICATIONS

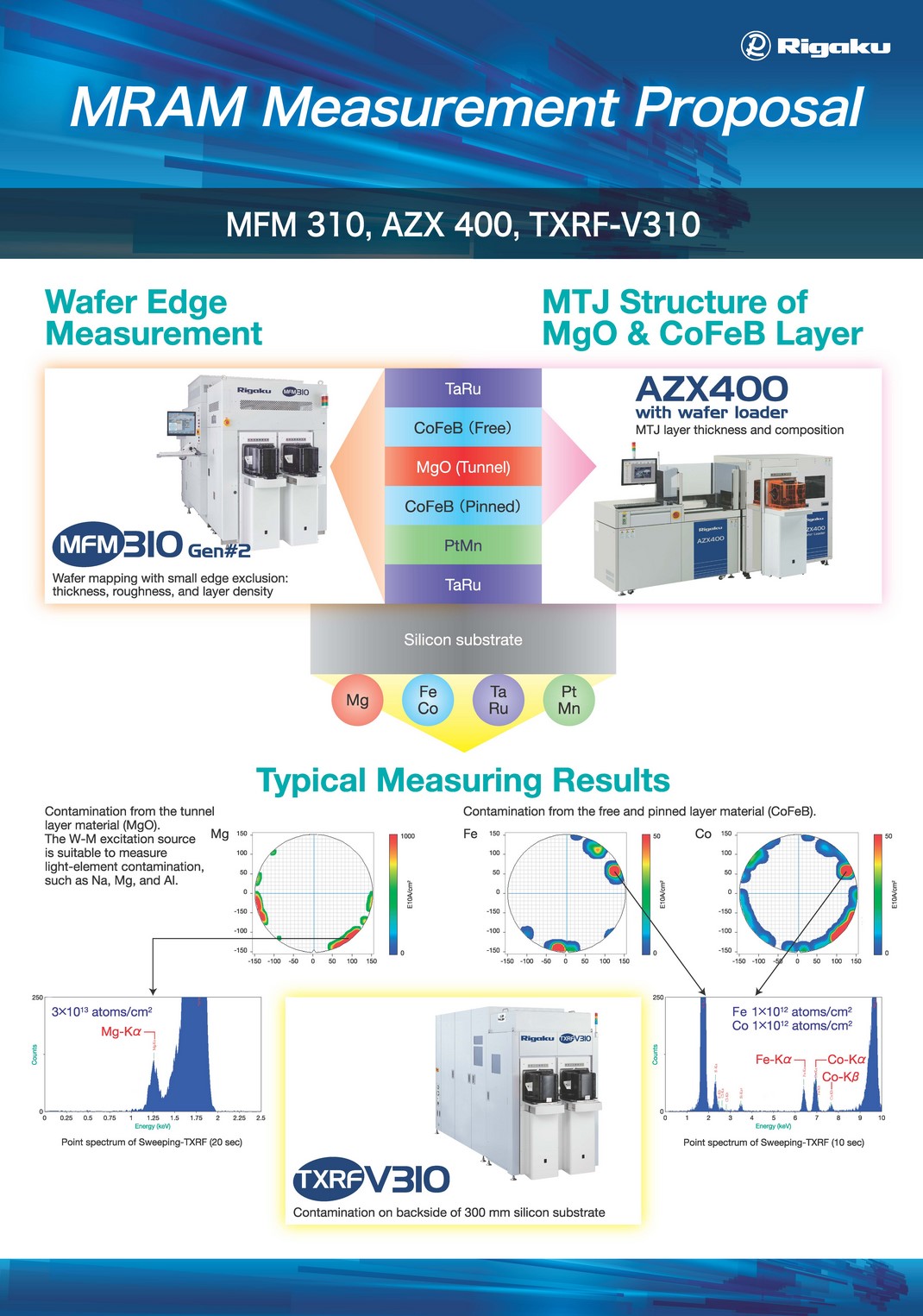

TXRF analysis can gauge contamination in all fab processes, including cleaning, litho, etch, ashing, films, etc. The TXRF-V310 can measure elements from Na through U with a single-target, 3-beam X-ray system, and a liquid nitrogen-free detector system.

The TXRF-V310 includes Rigaku's patented XYθ sample stage system, an in-vacuum wafer robotic transfer system, and new user-friendly windows software. These contribute to higher throughput, accuracy, precision, and easy routine operation.

Integrated VPD capability

Enables automatic VPD preparation of one wafer while a TXRF measurement is made on another for the highest sensitivity and high throughput. VPD-TXRF eliminates the operator variability that may occur with ICP-MS, and VPD-TXRF can be controlled entirely via factory automation. VPD recovery from selected areas, including the bevel area, is available.

Optional Sweeping TXRF software

Enables mapping of the contaminant distribution over the wafer surface to identify "hot spots" that can be automatically re-measured at higher precision.

Optional ZEE-TXRF capability overcomes the historical 15 mm edge exclusion of original TXRF designs, enabling measurements to be made with zero edge exclusion.

Optional BAC-TXRF

The capability enables fully-automated front-side and back-side TXRF measurements of 300 mm wafers with non-contacting wafer flipping.

FEATURES & BENEFITS

- Accepts 300 mm, 200 mm, and 150 mm wafers

- Wide range of analytical elements (Na~U)

- Light-element sensitivity (for Na, Mg, and Al)

- Single target 3-beam method and XYθ stage are unique to Rigaku, enabling highly accurate ultra trace analysis over the entire wafer surface

- Integrated, fully-automated VPD preparation for highest sensitivity

- 1E7 atoms/cm² detection limits

- Import measurement coordinates from defect inspection tools for follow-up analysis

- Multitasking: simultaneous VPD and TXRF operation for highest throughput

SYSTEM PARAMETERS |

SPECIFICATION |

| Technique | Total reflection X-ray fluorescence (TXRF) w/ vapor phase decomposition (VPD) |

| Benefit | Measurement of ultra-trace elemental surface contamination; 1E7 atoms/cm² detection limits |

| Technology | Automatic VPD preparation, three-beam excitation and automatic optics alignment |

| Core attributes | Automatic VPD, rotating-anode X-ray source, XYθ sample stage , liquid nitrogen-free detector, accepts 300 mm, 200 mm, and 150 mm wafers |

| Core options | GEM-300 automation software for full factory automation, SP-TXRF capability enables mapping of the entire wafer surface, ZEE-TXRF capability enables measurements to zero edge exclusion, BAC-TXRF capability enables fully-automated front-side and back-side measurements |

| Computer | Internal PC, MS Windows® OS |

| Core dimensions | 1200 (W) x 2050(H) x 2990 (D) mm |

| Mass | 1650 kg (core unit) |

| Power requirements | 3Ø, 200 VAC 50/60 Hz, 125 A |

Is surface contamination an issue for your semiconductor manufacturing process?

explore txrf-v310

< Click to play the video and view the TXRF-V310 in action.

Wafer surface contamination metrology Simultaneous VPD and TXRF for the highest throughput

- Wide range of analytical elements

- Light-element sensitivity

- Highly accurate ultra-trace analysis

- Multitasking: simultaneous VPD and TXRF operation for the highest throughput

- For up to 300 mm wafers

INTEGRATED VPD CAPABILITY

ZEE-TXRF SOFTWARE

BAC-TXRF CAPABILITY

Enabled automatic VPD preparation of one wafer while a TXRF measurement is made on another wafer for the highest sensitivity and high throughput. VPD-TXRF eliminates the operator variability that may occur with ICP-MS, and VPD-TXRF can be completely controlled via factory automation. VPD recovery from selected areas, including the bevel area, is available.

Optional Sweeping TXRF software enables mapping of the contaminant distribution over the wafer surface to identify "hot spots" that can be automatically re-measured at higher precision.

Optional ZEE-TXRF capability overcomes the historical 15 mm edge exclusion of original TXRF designs, enabling measurements to be made with zero edge exclusion.

Optional BAC-TXRF capability enables fully-automated front-side and back-side TXRF measurements of 300 mm wafers with non-contacting wafer flipping.

applications

Metal Contamination Monitoring

The TXRF series contributes to the next generation of process quality control.

TXRF analysis tool with the world’s first integrated VPN sample treatment system (patented).

From light elements to heavy elements, analytical needs are fulfilled.

A Highly Reliable Rotating-anode X-ray Source and Sweeping-TXRF Software Enable High-speed Contamination Mapping of Trace Elements

Wide Analyzable Element Range from Na to U with a 1-target, 3-beam Method

From Na, Mg, Al through U, Ultra-trace Contamination is Detected with High Precision.

consult an expert

TXRF-V310 RESOURCES

TRUSTED PARTNER

Pharmaceuticals have the power to change the world for the better, but before they can ever do that, they need to be proven safe and trustworthy. Here at Rigaku, we strive to make this a reality as the leading global scientific analytical instrumentation company specializing in X-ray and thermal analysis, and Raman spectroscopy.

CORPORATE MISSION

To contribute to the enhancement of humanity through scientific and technological development.

CORPORATE MOTTO

Value our customers, value our people, and value our technology