XTRaIA® MF-3000

ED-XRF and XRR

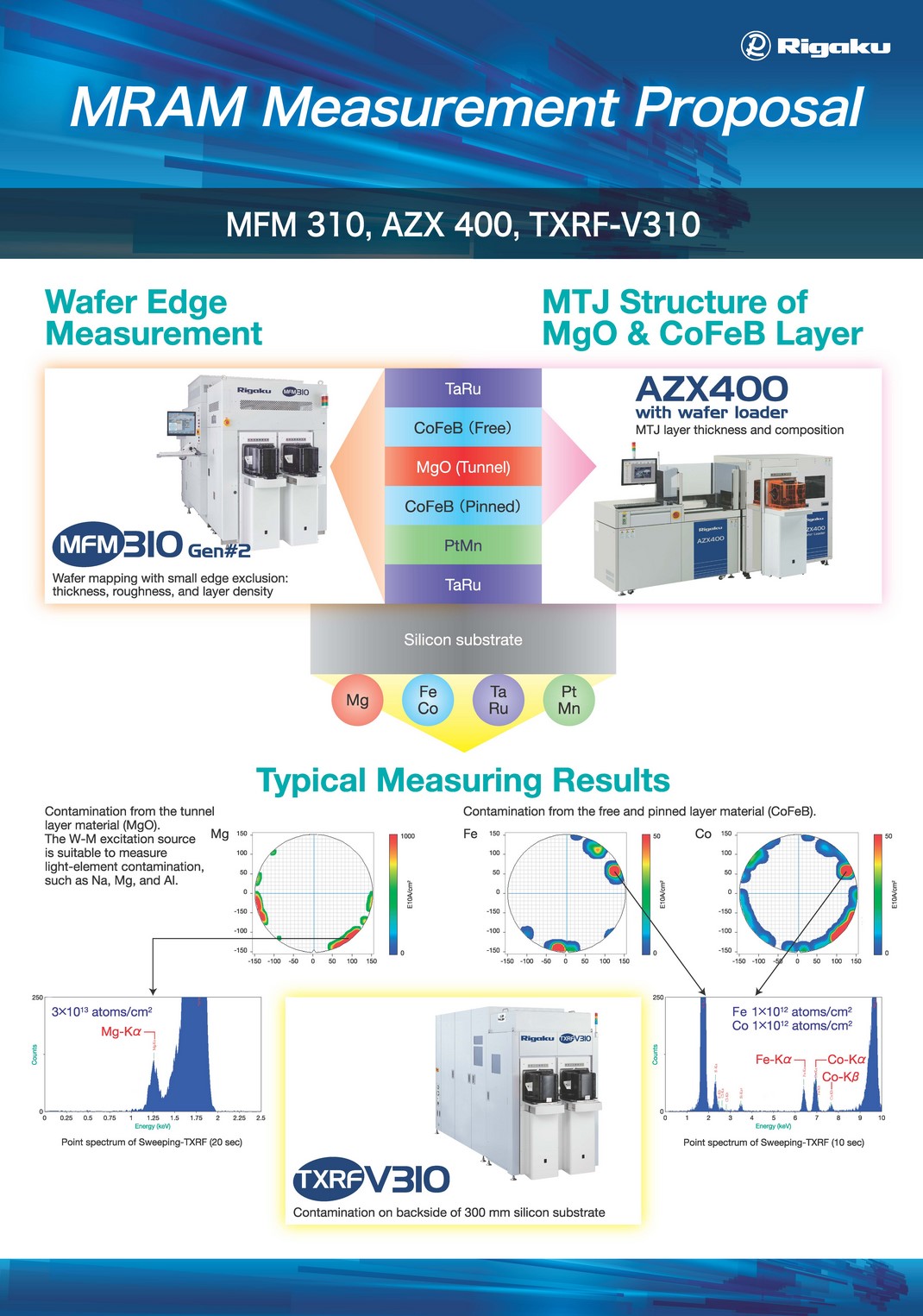

Blanket and patterned metal

layer thickness and composition

Former MFM310

XRR, ED-XRF, AND XRD METROLOGY | OPTIMIZED FOR HIGH-VOLUME MANUFACTURING

TECHNICAL SPECIFICATIONS

The Rigaku XTRAIA MF-3000 (formerly MFM310) performs high-precision measurements not possible by optical or ultrasonic techniques. This sophisticated X-ray metrology tool makes it practical to perform high-throughput measurements on product and blanket wafers ranging from ultrathin single-layer films to multilayer stacks.

Designed for high-volume manufacturing

The XTRAIA MF-3000 is designed with high-volume 200 mm and 300 mm manufacturing in mind: high-throughput thickness measurement by XRR and XRF, low-contamination wafer handling and pattern recognition-based position control for product wafer measurements, CE Marking and S2/S8 Compliance for semiconductor production clean room operation, compliance with GEM-300/HSMS and factory automation standards, high-reliability machine performance and low power consumption and cost of ownership.

COLORS™ enabling technology

COLORS™ X-ray optics were developed by Rigaku for the XTRAIA MF-3000 to enable measurements from small areas. COLORS beam modules couple a variety of XRF excitation sources with optics and are optimized to provide high brightness in small spots for a variety of thin film applications. With its own x-ray optics business, Rigaku is well-positioned develop and manufacture X-ray sources for current and future market needs.

FEATURES & BENEFITS

- Micro-spot X-ray beams and pattern recognition

- High-throughput, product-wafer measurements

- Wide range of materials and applications

- High resolution and precision covering thicknesses from Ångstroms to microns

- For 200 mm and 300 mm wafers

- Available with 300 mm factory automation

- Design based on SEMI S2 and SEMI S8

SYSTEM PARAMETERS |

SPECIFICATIONS |

| Technique |

X-ray reflectivity, fluorescence and diffraction |

| Benefit |

Measure ultra-thin single-layer films to multi-layer stacks |

| Technology |

Process micro-spot XRR, ed-XRF, and XRD with 2 FOUP load ports |

| Core attributes |

CE marked, S2 / S8 / GEM-300 / HSMS compliance |

| Core options |

Available with 300 mm factory automation |

| Computer |

Internal PC, MS Windows® OS |

| Core dimensions |

1400 (W) x 2050 (H) x 3410 (D) mm |

| Power requirements |

3Ø, 208 VAC 50/60 Hz, 2.5 kW |

Are you interested in characterizing patterned wafers with repeated structures?

explore XTRaIA® MF-3000

< Click to play the video and view the XTRAIA® MF-3000 in action.

ED-XRF and XRR

Blanket and patterned metal layer thickness and composition

- Metal layer thickness and composition by ED-XRF

- Simultaneous evaluation of film thickness, density, and roughness by XRR

- For up to 300 mm blanket and patterned wafers

XTRAIA MF-3000 RESOURCES

TRUSTED PARTNER

Pharmaceuticals have the power to change the world for the better, but before they can ever do that, they need to be proven safe and trustworthy. Here at Rigaku, we strive to make this a reality as the leading global scientific analytical instrumentation company specializing in X-ray and thermal analysis, and Raman spectroscopy.

CORPORATE MISSION

To contribute to the enhancement of humanity through scientific and technological development.

CORPORATE MOTTO

Value our customers, value our people, and value our technology