AZX 400

SEQUENTIAL WAVELENGTH-DISPERSIVE XRF SPECTROMETER

WITH ANALYTICAL FLEXIBILITY FOR PROCESS R&D AND LOW-VOLUME | HIGH-PRODCUT-MIX MANUFACTURING

TECHNICAL SPECIFICATIONS

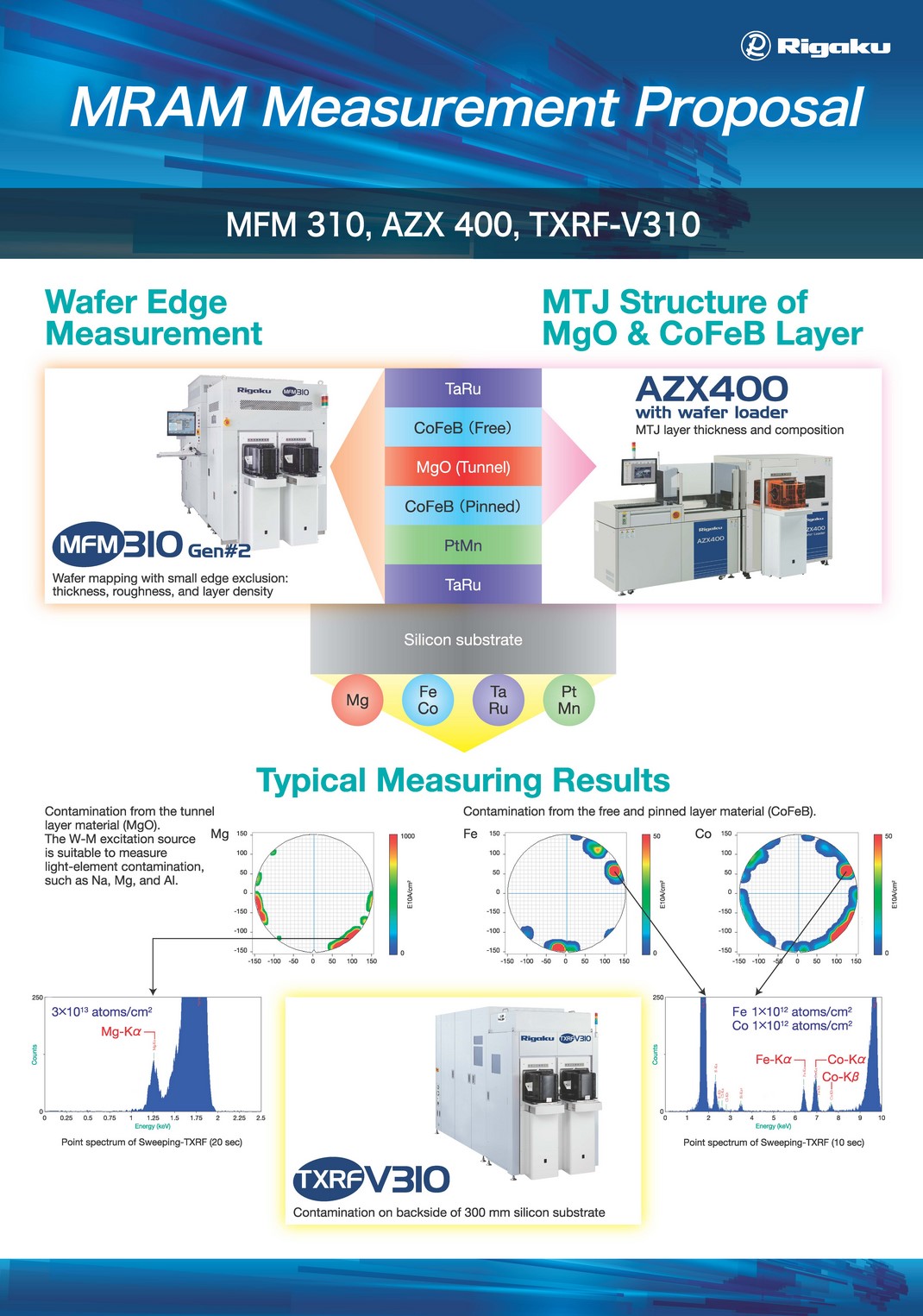

Rigaku's unique AZX 400 sequential wavelength dispersive X-ray fluorescence (WDXRF) spectrometer was specifically designed to handle very large and/or heavy samples. Accepting samples up to 400 mm diameter, 50 mm thick and 30 kg mass, this system is ideal for analyzing sputtering targets, magnetic disks, or for multilayer film metrology or elemental analysis of large samples.

Accepting samples up to 400 mm diameter, 50 mm thick and 30 kg mass, this system is ideal for analyzing sputtering targets, magnetic disks, or for multilayer film metrology or elemental analysis of large samples.

Benefits

- Analytical flexibility and Mapping capability

- Wide range of elements and sample types

- Ideal for high product mix / low volume operations and for process R&D

- For up to 400 mm samples

- Light elements analyzable with one system

- Enhanced productivity wafer auto-loader

- Analytical flexibility to measure elements from 5B-92U

AZX 400 accessories

- Sample camera with special lighting allows the analysis point to be viewed on screen

- Diffraction interference rejection provides accurate results for single-crystal substrates

- Fundamental Parameters software for thin film analysis

FEATURES & BENEFITS

- Large sample analysis, Up to 400 mm (diameter), Up to 50 mm (thickness), Up to 30 kg (mass)

- Sample adapter system, adaptable to various sample sizes

- Measurement spot, 30 mm to 0.5 mm diameter, A5-step automatic selection

- Mapping capability, allowing multipoint measurements

- Sample view camera (option),

- General purpose analyze Be - U, elemental range: ppm to %, and thickness range: sub Å to mm

- Diffraction interference rejection (option), accurate results for single-crystal substrates

- Compliance with industry standards, SEMI, CE marking

- Small footprint, 50% footprint of the previous model

SYSTEM PARAMETERS |

SPECIFICATIONS |

|

Technique |

Sequential wavelength dispersive X-ray fluorescence |

|

Benefit |

Flexibility to measure a variety of sample types, including |

|

Technology |

Analytical flexibility to measure elements from Be to U, well-suited for process R&D and low-volume, high product mix environment score |

|

Core attributes |

4 kW sealed X-ray tube, Sequential type goniometer, Primary beam filter; Measurement spot sizes 30, 20, 10, 1, and 0.5 mm (diameter) |

|

Core options |

Wafer Loader, SQX (Scan Quant. X) software, CCD Camera |

|

Computer |

External PC, MS Windows® OS, Software: film thickness/concentration simultaneous analysis software, Fundamental Parameter software for thin film analyses |

|

Core dimensions |

1376 (W) x 1710 (H) x 890 (D) mm |

|

Mass |

Approx. 800 kg (core unit) |

|

Power requirements |

3Ø, 200 VAC 50/60 Hz, 50 A |

XRF with customized sample adapter system

XRF with the available camera and special lighting

Traditional WDXRF analytical capabilities

Versatility to adapt to your specific sample types and analysis needs, this WDXRF spectrometer is adaptable to various sample sizes and shapes using optional (made-to-order) adapter inserts. With a variable measurement spot (30 mm to 0.5 mm diameter, with 5-step automatic selection) and mapping capability with multi-point measurements to check for sample uniformity, this uniquely flexible instrument can dramatically streamline your quality control processes.

The optional real-time camera allows the analysis area to be viewed within the software. The operator has complete certainty as to what is being measured.

All analytical capabilities of a traditional instrument are retained in this "large sample" variant. Analyze beryllium (Be) through uranium (U) with high-resolution, high-precision WDXRF spectroscopy, from solids to liquids and powders to thin films. Analyze wide composition ranges (ppm to tens of percent) and thicknesses (sub Å to mm). Optionally available is diffraction peak interference rejection, for optimal results for single-crystal substrates. Rigaku AZX 400 wavelength dispersive X-ray fluorescence (WDXRF) spectrometer complies with industry standards SEMI and CE.

APPLICATIONS

insulation films

| Sputtering target composition | |

| Isolation films | SiO2, BPSG, PSG, AsSG, Si₃N₄, SiOF, SiON,(...) |

| High-k and ferro-dielectric films | PZT, BST, SBT, Ta₂O₅, HfSiOx |

metal films

| Metal films | Al-Cu-Si, W, TiW, Co, TiN, TaN, Ta-Al, Ir, Pt, Ru, Au, Ni,(...) |

| Electrode films | doped poly-Si (dopant: B, N, O, P, As), amorphous-Si, WSix, Pt, (...) |

| Ferroelectric thin films | FRAM, MRAM, GMR, TMR; PCM, GST, GeTe |

others

| Solder bump composition | SnAg, SnAgCuNi |

| MEMS | thickness and composition of ZnO, AlN, PZT |

| SAW device process | thickness and composition of AlN, ZnO, ZnS, SiO2 (piezo film); Al, AlCu, AlSc, AlTi (electrode film) |

| Other doped films |

(As, P), trapped inert gas (Ne, Ar, Kr, etc.), C (DLC) |

AZX 400 RESOURCES

TRUSTED PARTNER

Pharmaceuticals have the power to change the world for the better, but before they can ever do that, they need to be proven safe and trustworthy. Here at Rigaku, we strive to make this a reality as the leading global scientific analytical instrumentation company specializing in X-ray and thermal analysis, and Raman spectroscopy.

CORPORATE MISSION

To contribute to the enhancement of humanity through scientific and technological development.

CORPORATE MOTTO

Value our customers, value our people, and value our technology