WD-XRF

Wavelength-Dispersive X-ray Fluorescence

TECHNIQUE

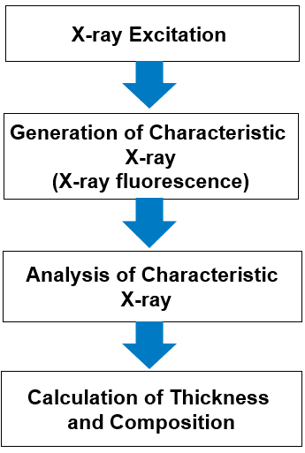

This x-ray technique employs a high-power x-ray source (typically 4kW Rh) to excite the characteristic (fluorescence) x-rays from the elements in a specimen.

WD-XRF spectrometers are of two types, sequential and simultaneous.

A sequential spectrometer measures elements of interest one at a time with the automatic adjustment of crystals and x-ray optics. Sequential spectrometers offer analytical flexibility in process R&D and low-volume, high-product-mix manufacturing environments where measurement throughput is not of primary concern.

A simultaneous spectrometer is configured with multiple, dedicated channels to maximize measurement throughput in high-volume manufacturing environments where the elements of interest are not likely to change frequently.

Because fluorescence x-rays are scattered uniformly in all directions, it is typically possible to configure a simultaneous spectrometer with up to 20 channels. A "fixed" or "dedicated" channel is comprised of a natural or synthetic crystal and a counter (scintillation, sealed-proportional, or flow proportional) optimized to select the energy corresponding to the spectral line of the element of interest. A "scanning channel" employs a crystal on a goniometer that can be oriented to select energies from a range of elements (Ti-U). A scanning channel offers analytical flexibility but a fixed channel offers better optimization for a specific element of interest. Fixed channels are required to measure elements lighter than Ti.

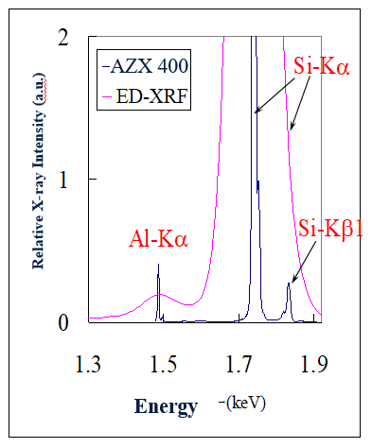

The defining aspect of a WDXRF spectrometer is the use of a (physical) crystal to achieve energy resolution. In contrast, energy-dispersive x-ray fluorescence (EDXRF) spectrometers rely on detector electronics to achieve energy resolution. Generally, WDXRF provides much higher energy resolution than EDXRF. Higher energy resolution can minimize or eliminate peak overlap issues.

Sample: 20 nm Al

Si-Kα energy resolution: 7.6 eV WDXRF (AZX 400), 103 eV EDXRF

WD-XRF requires calibration to relate the measured x-ray intensities to the parameter of interest, e.g. thickness and/or composition. There are different approaches to XRF calibration, two being "Empirical" and "Fundamental Parameter." The Empirical approach involves measuring one or more standard samples that have been characterized by an independent technique, such as non-destructive XRR or "sister wafers" characterized by destructive wet-chemical analysis.

The Fundamental Parameter approach can reduce the number of required calibration standards. See the Rigaku Journal article below for more information about the Fundamental Parameter approach for XRF calibration of thickness and composition of thin films.

Thickness and composition analysis of thin films samples using FP method by XRF analysis

Rigaku Journal 33(2), 17-21, 2017

Introduction

X-ray fluorescence spectroscopy (XRF) is an elemental quantification analysis method for inorganic and metallic compounds. Sample preparation is simple and does not require solid samples to be dissolved, as is necessary for wet chemical analysis techniques. The fundamental parameter (FP) method implements quantitative analysis without type standards. The XRF technique has been widely accepted not only for bulk analysis but for thin film analysis in plating and electronic materials. With the thin film FP method, the thickness and composition of a thin film can be simultaneously determined, and the software is able to handle even complex multilayers. This article explains the basic principles of XRF thin film analysis; the depth of an XRF measurement and an overview of the thin film FP method. An ITO (indium tin oxide) thin film is analyzed as an example, and software parameter settings and reference material settings are also described.

RECOMMENDED RIGAKU SEMICONDUCTOR METROLOGY TOOLS

AZX 400Sequential WD-XRF spectrometer

Analytical flexibility for process R&D and low-volume manufacturing and high-product-mix |

WDA-3650SIMULTANEOUS WD-XRF spectrometer

Film thickness and composition measurements on blanket wafers |

Waferx 310SIMULTANEOUS WD-XRF spectrometer

In-line, simultaneous WD-XRF spectrometer for high-volume manufacturing |