WD-XRF APPLICATION

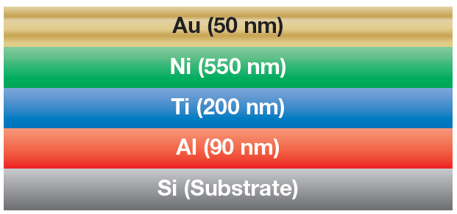

THICKNESS CHARACTERIZATION OF A POWER DEVICE

BACKSIDE ELECTRODE

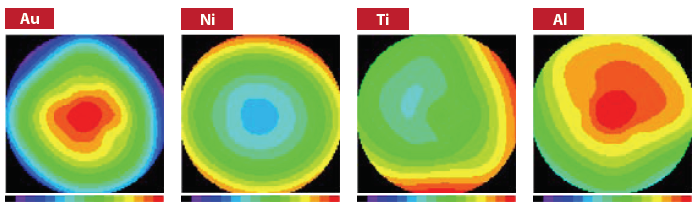

WD-XRF can monitor metal film thickness and uniformity with high precision and throughput.

All four layers, even the bottom Al, can be analyzed simultaneously thanks to the high-power (4 kW) X-ray source and the FP method.

elements measeured by wd-xrf

| X Y | Au | Ni | Ti | Al |

| nm | nm | nm | nm | |

| Average (nm) | 49.3 | 551.3 | 198.2 | 89.5 |

| Maximun (nm) | 50.4 | 557.3 | 201.2 | 91.1 |

| Minimun (nm) | 48.1 | 544.8 | 195.3 | 87.9 |

| Range (nm) | 2.3 | 12.5 | 5.9 | 3.23 |

| Sigma (nm) | 0.90 | 3.59 | 1.61 | 0.87 |

| RSD (%) | 1.82 | 0.65 | 0.81 | 0.97 |

RECOMMENDED RIGAKU SEMICONDUCTOR METROLOGY TOOLS

AZX 400

Sequential WDXRF spectrometer for elemental analysis and thin-film metrology of large and/or heavy samples

WDA-3650

Simultaneous WDXRF spectrometer for wafer metal film metrology; up to 200 mm wafers

WAFERX 310

In-line, simultaneous WDXRF spectrometer for wafer metal film metrology; up to 300 mm wafers